Did you know that the very chemicals that protect us from fires might also harm our environment? PFAS, or per- and polyfluoroalkyl substances, are chemicals that have a bit of a double-edged reputation. On one hand, they’re incredibly useful thanks to their resistance to heat, water, and oil. On the other hand, they’re dubbed “forever chemicals” because they persist in the environment and the human body. This makes them both a marvel and a concern. Let’s dive into their role in fire safety, the trade-offs they bring, and the trends shaping the future of fire-resistant materials.

The Role of PFAS: Why Are They Indispensable?

PFAS have carved out a significant role in fire safety, but why are they so indispensable? Let’s break it down:

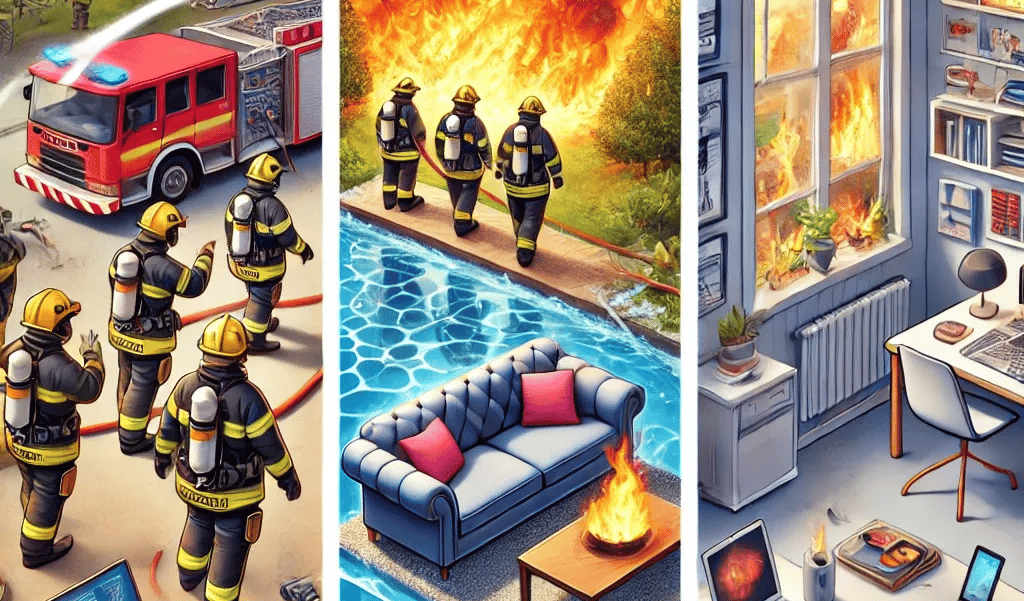

Firefighting Foams: Think of PFAS-based aqueous film-forming foams (AFFF). They’re excellent at tackling fires involving flammable liquids by forming a barrier that cuts off oxygen. This makes them essential in high-risk areas like airports and industrial sites where fires can escalate quickly.

Coatings and Treatments: PFAS are used to create fire-resistant coatings for products like furniture and outdoor gear. These coatings meet stringent safety standards, providing added protection. For example, PFAS-treated upholstery can significantly slow fire spread in homes.

Electronics: In gadgets like smartphones and laptops, PFAS helps manage heat and reduce the risk of fires caused by overheating. This makes them a crucial component in ensuring the safety and longevity of electronics.

The Catch with PFAS: Benefits vs. Drawbacks

While PFAS are incredibly useful, there’s a catch—they come with some significant drawbacks. Let’s explore:

1. Environmental Impact

PFAS are often called “forever chemicals” because they don’t break down. Once they enter the environment, they accumulate in water, soil, and even air, causing long-term pollution issues. For instance, PFAS contamination in drinking water has become a pressing global issue.

2. Health Concerns

Exposure to PFAS is linked to serious health risks like hormone disruption, immune system problems, and even cancer. When PFAS-treated materials degrade or are burned, they can release toxic byproducts. This is especially concerning for communities near PFAS manufacturing sites.

3. Regulatory Challenges

Governments are stepping in to address the risks associated with PFAS:

EU REACH: The European Union’s REACH program has identified several PFAS as Substances of Very High Concern (SVHC), and the EU is pushing for a phase-out of non-essential uses.

United States: States like California have banned PFAS in firefighting foams and certain consumer goods. Meanwhile, the Environmental Protection Agency (EPA) is ramping up efforts to regulate PFAS under the Toxic Substances Control Act (TSCA).

4. Performance vs. Sustainability

Here’s the dilemma: PFAS provide unmatched fire safety performance, but their environmental cost is high. For example, industries like aerospace rely on PFAS for safety-critical applications, but finding equally effective and sustainable alternatives is a challenge.

What’s Next? Exciting Innovations in Fire-Resistant Materials

As concerns around PFAS grow, innovation is stepping up to the plate. Here are some exciting trends leading the charge:

1. PFAS-free Firefighting Foams

Alternatives to traditional PFAS-based foams are emerging, focusing on biodegradable and environmentally friendly formulations. These new options aim to deliver the same fire suppression capabilities without lasting environmental harm. For example, companies are now offering foams used in municipal firefighting and industrial settings, such as fluorine-free firefighting foams for oil refineries and chemical plants.

2. Bio-based Flame Retardants

Natural materials like clay and plant-based additives are gaining popularity. These bio-based flame retardants are especially attractive in industries focused on sustainability, such as construction and textiles. For example, clay-based retardants are used in building insulation materials, while plant-derived additives are incorporated into flame-resistant fabrics for curtains and upholstery.

3. Advanced Material Science

Innovations like graphene-based coatings and nanotechnology are paving the way for fire-resistant materials that don’t rely on toxic chemicals. For example, graphene coatings are being tested in smartphones to enhance thermal management and fire resistance, while nanotechnology-based solutions are used in aerospace materials to improve fire safety. These solutions are particularly promising for consumer electronics and other high-tech applications.

4. Circular Economy Approaches

The idea here is simple: design fire-resistant products that can be recycled or biodegraded at the end of their life. This approach reduces waste while maintaining high safety standards. For example, fire-resistant fabrics made from recyclable polyester are being developed for use in curtains and upholstery, and biodegradable insulation materials are gaining traction in the construction industry.

Striking the Balance: Safety Meets Sustainability

Here’s the challenge: How do we balance the benefits of PFAS with their undeniable drawbacks? Industries need to prioritize sustainable innovations, adapt to stricter regulations, and find ways to ensure safety without compromising the environment. Collaborations between manufacturers, researchers, and regulators are helping accelerate the shift toward safer alternatives.

Conclusion

PFAS have been a cornerstone of fire safety for decades, but their environmental persistence is a growing concern. As industries innovate and move toward greener alternatives, the trade-offs of PFAS usage will guide the future of fire-resistant materials. By focusing on sustainability and collaboration, we can ensure the next generation of solutions is not only effective but also environmentally responsible.