What is Functional Safety?

Have you ever wondered what keeps your car’s airbag from deploying at the wrong moment or ensures that a pacemaker never skips a beat? That’s where functional safety comes in! It’s all about making sure systems work safely, even when something goes wrong.

Here’s how it works: Every product is made up of different functions—and each of these functions can potentially fail. For example, imagine the braking system in your car. If something goes wrong with the braking function, it could lead to a hazardous event, like the brakes not working when you need them most. Functional safety is like a safety net that catches these faults before they cause harm to people.

The goal of functional safety is simple: keep the system safe. It does this by identifying possible faults, preventing them from happening, or minimizing their impact if they do. So, whether it's your car, a medical device, or even an industrial robot, functional safety ensures that these systems stay within a safe operating range, protecting you from potential hazards.

The Standards That Matter

Just like seatbelts and airbags are non-negotiable in cars, there are specific rules and standards to ensure that products are safe. These standards provide a clear framework for companies to follow so that systems operate safely—even when something fails.

ISO 26262 (For Cars): In modern vehicles, especially with all the electronics, ISO 26262 is the bible for safety. It ensures everything from braking systems to cruise control continues to function safely, even during a fault.

IEC 61508 (For a Wide Range of Industries): Often called the "mother" of functional safety standards, this one applies to pretty much any industry—whether you’re working with factory robots, power plants, or even theme park rides!

DO-178C (For Planes): In aviation, safety is everything. DO-178C ensures that the software running an airplane—from autopilot systems to navigation—is safe and reliable, reducing risks at every level.

These standards are crucial because they make sure that safety is built into the design from the very beginning, not as an afterthought. They also help create consistency, meaning a product made in one country is just as safe as one made in another, thanks to these global rules.

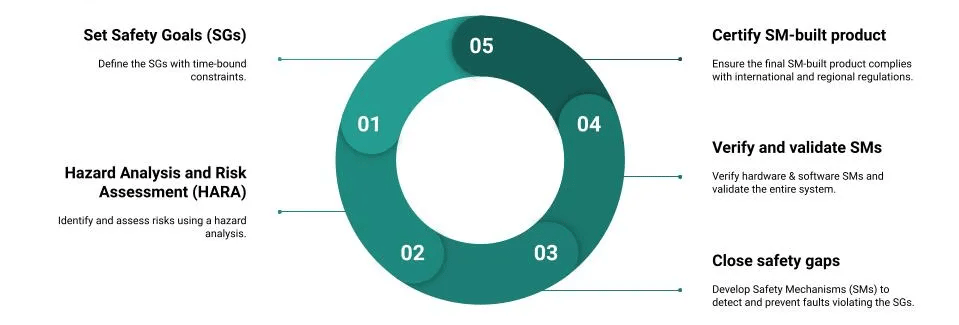

The Functional Safety Lifecycle

Building a safe product isn’t a one-and-done process—it’s a journey that requires careful planning and constant attention. Let’s break it down like planning the perfect road trip:

Spotting the Risks (Hazard Analysis): First, you need to identify what could go wrong. If you’re building an electric vehicle, you might worry about the battery overheating or the braking system failing. Functional safety steps in here, making sure these risks are identified early on.

Building with Safety in Mind (Design): Once the risks are identified, you can design ways to deal with them. For instance, backup systems or additional safety features, like automatic braking if a sensor detects an issue, get built into the design.

Test, Test, Test (Implementation and Validation): After designing your system, you need to test it—thoroughly. Think of it like testing a seatbelt in different crash scenarios. Functional safety testing ensures the system behaves safely in real-world conditions, even when something goes wrong.

Keeping It Safe (Maintenance): The journey doesn’t end when the product hits the market. Regular maintenance and updates are essential to ensure it keeps operating safely. It’s like giving your car a tune-up—everything needs to stay in tip-top shape.

Key Concepts in Functional Safety

There are a few important ideas that help make functional safety work:

Safety Integrity Levels (SIL): Think of these as safety ratings. The higher the SIL, the more reliable the safety function needs to be. For example, a nuclear reactor would need a very high SIL (level 4), while a less critical system like factory lighting might only need a lower SIL (level 1).

Automotive Safety Integrity Levels (ASIL): In the automotive world, ASIL is used to assess how risky a system’s failure could be. Something like a car’s braking system will have a high ASIL, while something less critical, like controlling the radio, will have a lower one.

Fault Tolerance and Redundancy: This is where backup systems come in. For example, if one sensor fails, a redundant sensor takes over to keep the system running smoothly. This ensures that no single fault leads to an unsafe condition.

Fail-Safe vs. Fail-Operational: In some cases, it’s best if a system shuts down when it encounters a fault (fail-safe), like shutting off a gas valve if a leak is detected. In other cases, the system needs to keep running safely even if something fails (fail-operational), like an airplane’s flight control system, which must continue working even when parts of it fail.

New Tech, New Challenges

As technology keeps evolving, functional safety faces new challenges. Let’s take a look at how this discipline is keeping up with the latest trends:

Autonomous Vehicles and AI: Self-driving cars are filled with complex systems that all need to work together safely. Functional safety makes sure that if one system—like a camera or sensor—fails, there’s a backup plan. But the tricky part is ensuring that these systems are reliable in all possible situations.

Cybersecurity Concerns: In today’s connected world, safety and security go hand in hand. A system that’s safe might not stay that way if someone hacks into it. That’s why functional safety now has to consider cybersecurity as part of the overall picture, especially for things like smart devices or connected vehicles.

Regulations Keep Evolving: As technology changes, so do the rules. Governments are constantly updating safety regulations to cover new technologies, like drones or AI-powered machines. Functional safety has to stay ahead of the game to keep up with these new rules.

Case Studies: Functional Safety in Action

Let’s take a peek into the real world, where functional safety is hard at work:

Tesla’s Autopilot: Tesla’s semi-autonomous driving system, Autopilot, is a marvel of technology, but it also shows the importance of functional safety. While Autopilot works great most of the time, there have been incidents where the system failed to react properly, reminding us of the importance of rigorous testing and constant improvement in these high-tech safety systems.

Pacemakers and Medical Devices: A pacemaker’s job is simple yet critical: keep your heart beating steadily. Functional safety ensures that if something goes wrong, the device either corrects the issue or shuts down safely, alerting doctors before any harm is done. Since these devices are implanted in patients, safety has to be flawless.

Boeing 737 MAX: On a more serious note, the Boeing 737 MAX tragedy highlights what can happen when functional safety systems don’t perform as expected. The MCAS system, designed to prevent the plane from stalling, malfunctioned and contributed to two catastrophic accidents. This case underscores the life-and-death importance of getting functional safety right, especially in complex systems like aviation.

Wrapping Up

As we move deeper into the era of automation, electric vehicles, and AI-driven systems, functional safety has never been more important. The stakes are high—when systems fail, the consequences can be serious. But by understanding the risks, designing for safety, and following global standards, we can ensure these products are safe and reliable.

For companies, functional safety isn’t just about avoiding risks—it’s about building trust with customers. When people know your product is safe, they can use it with confidence. And in today’s tech-driven world, that trust is everything.